Lathe Cleaning:

A new lathe must be cleaned first from the protective layer of grease and properly lubricated before placed in service.Please take the time to read the operating manual that Optimum Machines provides with OptiD180 (PDF file available at download page). In case that you don’t fully understand the instructions or if you need further guidance you can contact with Optimum Machines customer support service. They were very helpful when I had questions, so don’t hesitate to e-mail them.

lathe Disassembly

Lathe Assembly and Lubrication

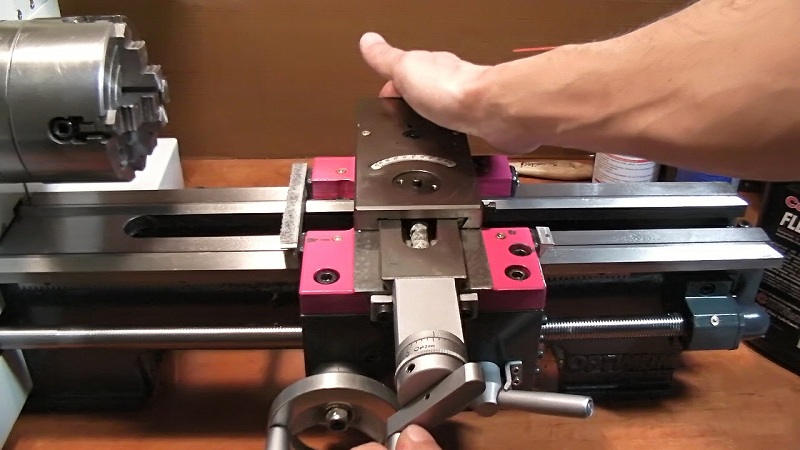

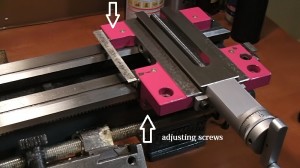

Set the cross slide back in place. Set the cross slide back in place. |

Adjust the gib. Remember should not be too tight , should be free to move but without the slightest amount of play. Adjust the gib. Remember should not be too tight , should be free to move but without the slightest amount of play. |

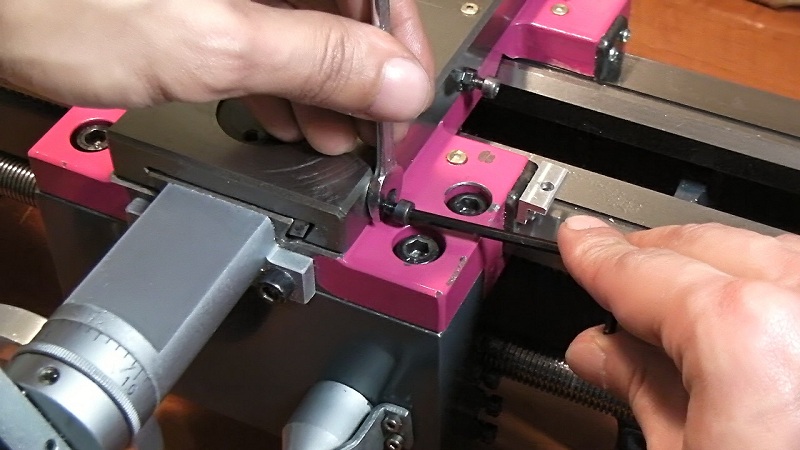

Set the dovetail guide of the top slide and lubricate like so. Set the dovetail guide of the top slide and lubricate like so. |

Use motorcycle chain grease and sae 30 oil for top slide also. Use motorcycle chain grease and sae 30 oil for top slide also. |

Set the top slide and adjust the gib accordingly. Set the top slide and adjust the gib accordingly. |

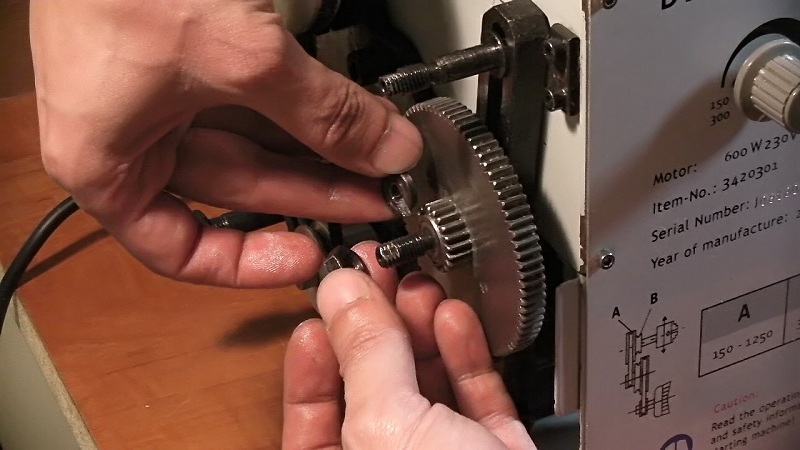

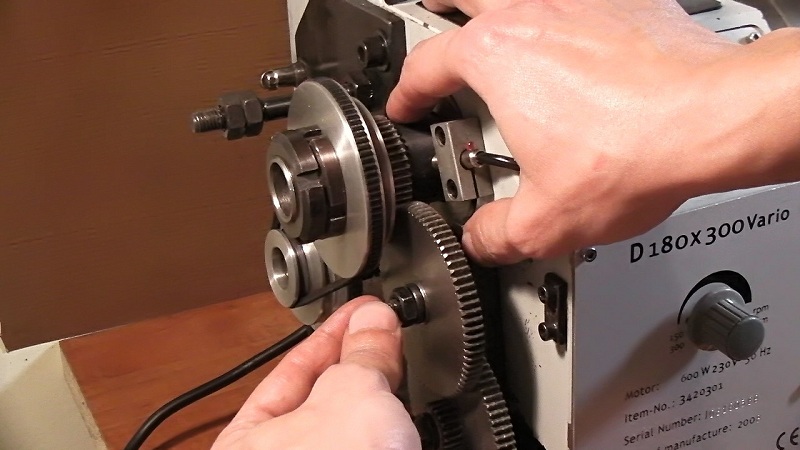

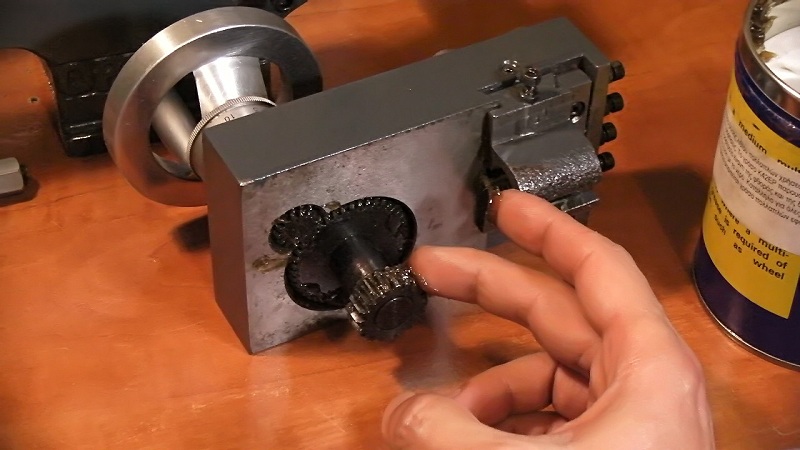

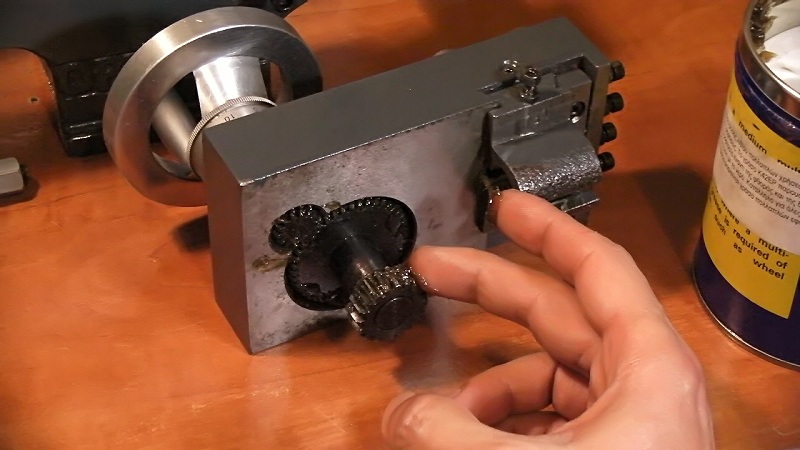

Install the gears gib the collar and the gears shafts. Apply grease to the gears shafts. Install the gears gib the collar and the gears shafts. Apply grease to the gears shafts. |

I will install the 0.1mm per revolution gear combination. First the set of gears in the middle. Set the locking washer and tighten the nut by hand. I will install the 0.1mm per revolution gear combination. First the set of gears in the middle. Set the locking washer and tighten the nut by hand. |

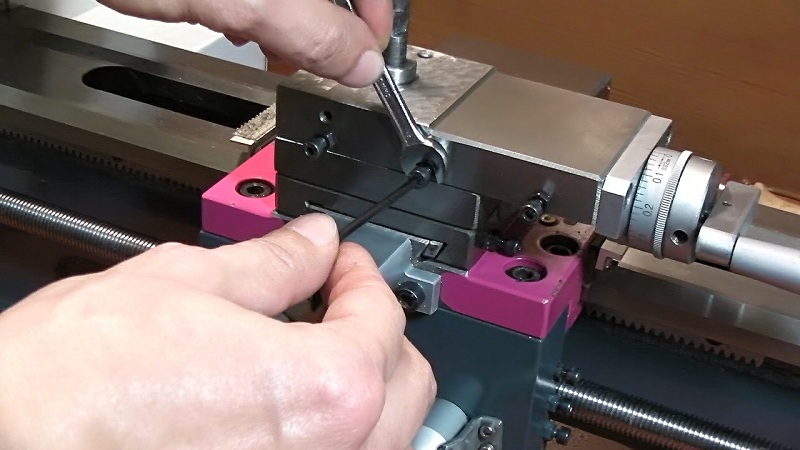

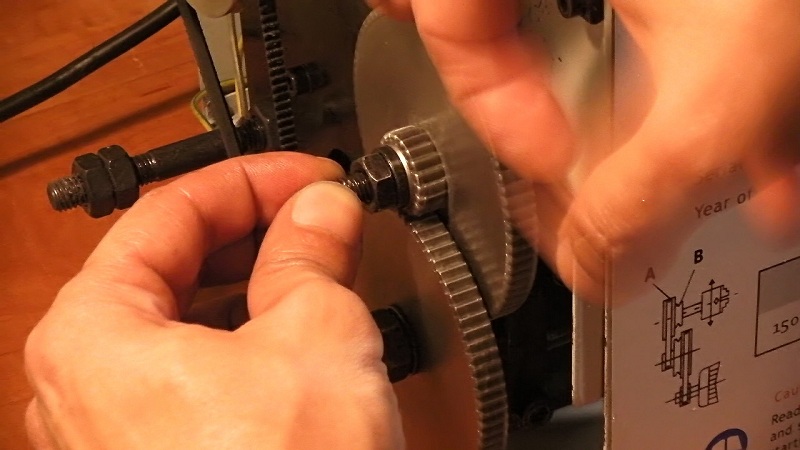

Use a 6mm wrench and loosen slightly the gear shaft. Hold the gear shaft loosen and tighten the nut. Use a 6mm wrench and loosen slightly the gear shaft. Hold the gear shaft loosen and tighten the nut. |

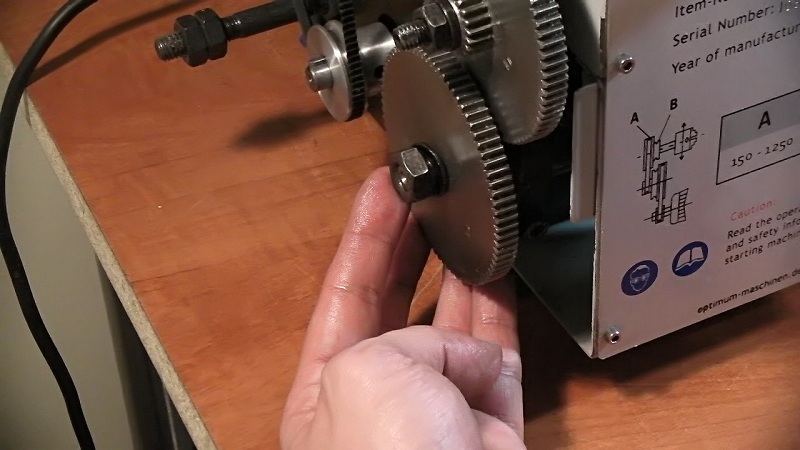

Tighten the gear shaft by hand and spin the gear to check that rotates freely. Tighten the gear shaft by hand and spin the gear to check that rotates freely. |

Install the gear to the lead screw. Hold the gear with a rag and tighten the nut. Install the gear to the lead screw. Hold the gear with a rag and tighten the nut. |

Release the gear set at the middle and drive it against the bottom gear. Rise just a little bit the shaft and tighten by hand. Spin the gears to check that rotates freely. If not rise the gears a little more and keep testing until you find the right spot. Release the gear set at the middle and drive it against the bottom gear. Rise just a little bit the shaft and tighten by hand. Spin the gears to check that rotates freely. If not rise the gears a little more and keep testing until you find the right spot. |

Use the 6mm wrench and tighten the shaft progressively as you spin the gears at the same time. Use the 6mm wrench and tighten the shaft progressively as you spin the gears at the same time. |

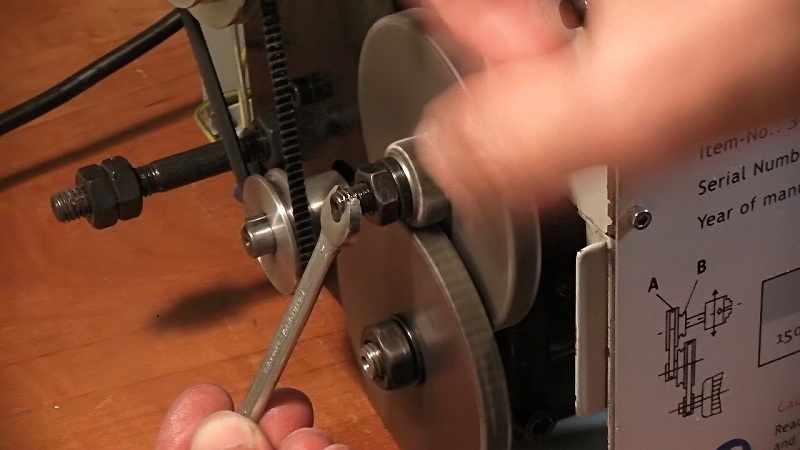

Install the last set of gears like so. Install the last set of gears like so. |

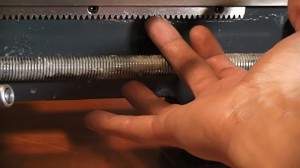

Push the gears against the toothed wheel. Push the gears against the toothed wheel. |

Spin the chuck by hand a few times and the gears will get the correct gap between the toothed wheel. Spin the chuck by hand a few times and the gears will get the correct gap between the toothed wheel. |

Apply a good amount of grease to slide gears and lubricate all strip metal surfaces with machine oil .

Apply a good amount of grease to slide gears and lubricate all strip metal surfaces with machine oil .